The key to the success of any SCADA system depends whether you choose between PLC and RTU units. Selecting one over the other will positively impact your business operations’ efficiency and effectiveness, while choosing the other might not generate the desired results.

Determining which one is better for your business ultimately depends on the different benefits and the functionalities of each unit. By analyzing the key components of each unit, you can determine which unit is best for your business’ operations.

The Basics of These Units

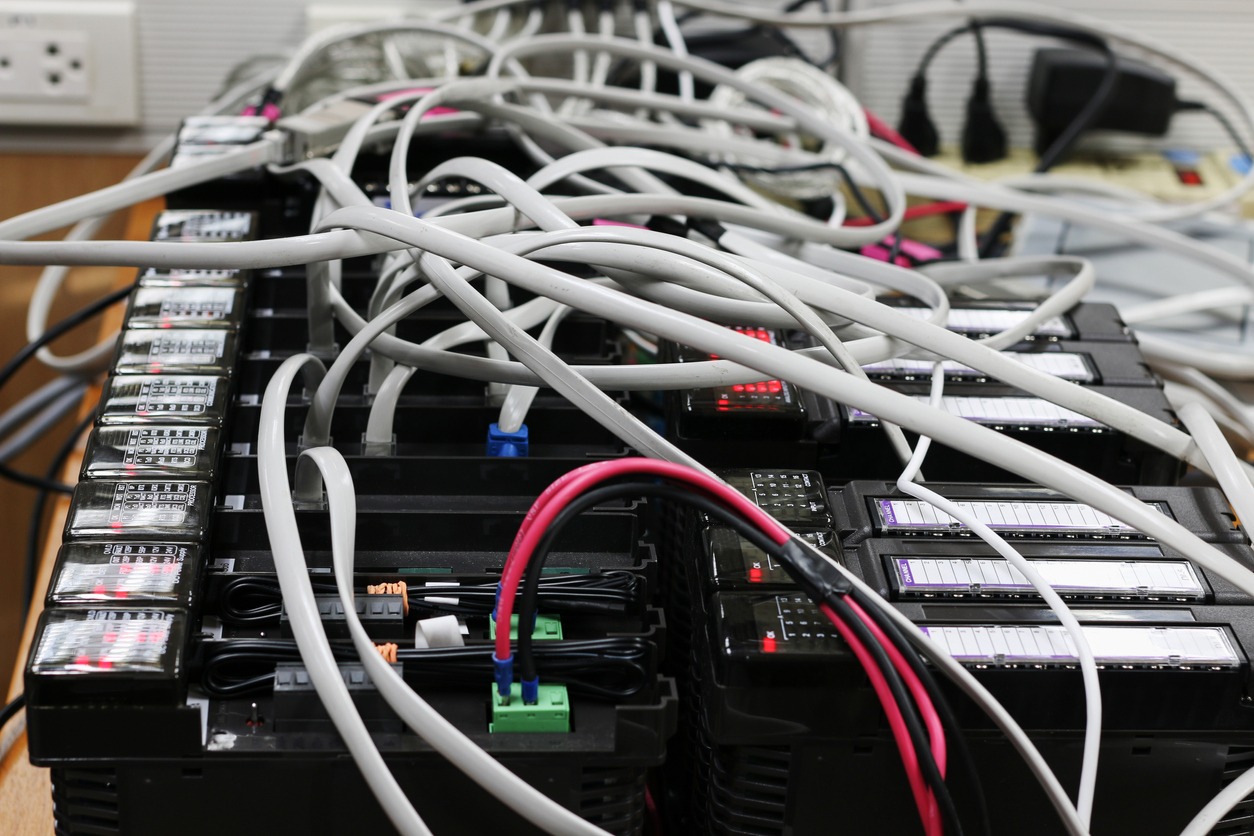

These two terminal units are necessary for providing the central hub with real-time information and breakdowns of what is occurring around the facility. This central hub oversees the overall performance of the RTUs (“Remote Terminal Units”) and PLCs (“Programmable Logic Controller”), providing in-field operators with the opportunity to make changes to ensure that all systems are operating as expected.

Both have similar proprietary devices and are used for different associated environments in high-pressure industries, such as oil and gas, energy, aviation, manufacturing and public sectors.

RTU is an electronic device controlled by a microprocessor, and its main use is to interface with SCADA and be present physically. By using supervisory system messages to control all the devices connected to the SCADA, RTU transmits all the telemetry data.

On the other hand, PLC is more suitable as a wireless communication device, and works better in geographical telemetry areas, such as production lines or plants. However, it shares similar functions and system alignments with RTU units and other proprietary tools.

The Differences Between The Two Units

Distance of Communication

As RTUs are controlled by a microprocessor, all the information is transmitted to the network through telemetry data. Therefore, they are used in wider geographical telemetry, as the reach is more useful in these situations.

PLCs are a digital computer and are best used for automating electromechanical processes, such as assembly lines, light fixtures and operating systems. As such, they won’t be used in wider geographical locations.

Capacity Of The Terminal Units

With close to 30 inputs, several outputs and a direct line of communication, RTUs require a substantial amount of capacity to operate. It’s a larger system in general, and therefore, requires a lot of excessive power and processes, but you will get a larger network connection.

PLC, being a small system, means less capacity. With its small number of digital and analog inputs and a single interface, it’s the less powered unit to use.

The Installation Requirements

This is where things might be tricky, and where having an experienced industrial and electrical company (https://www.cdncontrols.ca/) can make a difference.

RTUs are usually pre-set for deployment into any SCADA system, so the design is already composed of an embedded configuration application that can easily be installed. It just needs a standard browser connection for setup. It’s an easier system to install.

PLC units, on the other hand, sometimes require additional programming to perform their monitoring role, as it will be impacted by what you need it for, how you plan to use it and how it interacts with the central hub.

What Works For Your SCADA System?

Suppose you are operating a vastly massive and challenging operation. In that case, an RTU will be beneficial for your business, as you will require a system that is more robust and better suited to the high demands of an extensive system.

For less complex operations and units, a PLC is the better choice. They are better for simpler electromechanical processes and can provide precise data and help you keep your systems under control.

Deciding to choose between these two systems depends on your business operations and your marketing goals. Choosing the right one will make a massive difference to the overall operation and maintenance of your workplace, delivering the results that you want for your business. This will ultimately decide which unit is best for your business.

Make sure you speak to a SCADA professional so you know what you are purchasing and that the system covers all of your needs.